ENGINEERING

MEG offers comprehensive design solutions in the engineering industry by applying cost-effective and time-sensitive designs that prevent problems from arising during construction, enable operations to run smoothly, meet regulations, oversee budgets, monitor schedules, and deliver high-quality projects to our customers.

MEG offers comprehensive design solutions in the engineering industry by applying cost-effective and time-sensitive designs that prevent problems from arising during construction, enable operations to run smoothly, meet regulations, oversee budgets, monitor schedules, and deliver high-quality projects to our customers.Because of the effective skills of our dedicated employees, we have become leaders in providing engineering, design, and construction services for a variety of projects. Our staff performs technical and financial feasibility studies, provide construction quality assurance, prepare proposals and bid documents, deliver presentations, negotiate with the client, and procure services.

Our flexibility in offering viable alternatives and delivering high-quality services and solutions makes MEG the firm of choice when it comes to engineering a project within budget and on schedule.

PROCUREMENT

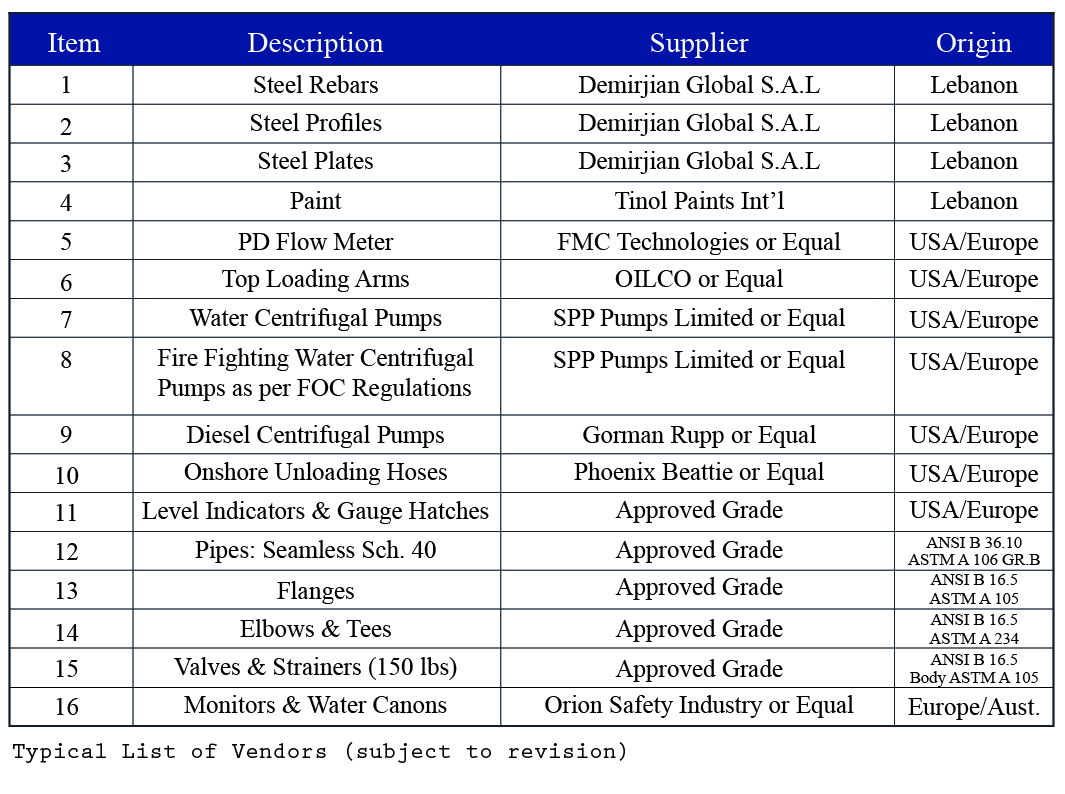

Leveraging vast market knowledge and experience in the engineering industry, MEG has established an extensive network of suppliers and manufacturers, enabling us to efficiently source anything our customers require from qualified sources in every region of the world. With renowned experience in executing large projects ranging from sea lines, pipelines, to storage tank farms and other industrial projects, MEG targets value, quality and compliant solutions to save our customers time and money.

Leveraging vast market knowledge and experience in the engineering industry, MEG has established an extensive network of suppliers and manufacturers, enabling us to efficiently source anything our customers require from qualified sources in every region of the world. With renowned experience in executing large projects ranging from sea lines, pipelines, to storage tank farms and other industrial projects, MEG targets value, quality and compliant solutions to save our customers time and money.Our proven strategies have led to the successful procurement and delivery of thousands of material items and equipment, covering project sites across the region.

CONSTRUCTION

We have been leaders in the mechanical construction industry for more than 45 years. Our skilled team of professionals understands the dynamics of fast-track schedules and rigorous construction standards, and is known for solving problems creatively to achieve optimum results. By meeting our customers’ needs, we design and build for the consumer—the citizens and visitors of the communities directly impacted by our efforts.

MEG is a primary contractor working in various sectors, including public and private; with contracts ranging from fixed-price, cost-plus, design-build-operate, to fast-track construction projects. We perform our work in diverse disciplines. Our construction and installation capabilities include::

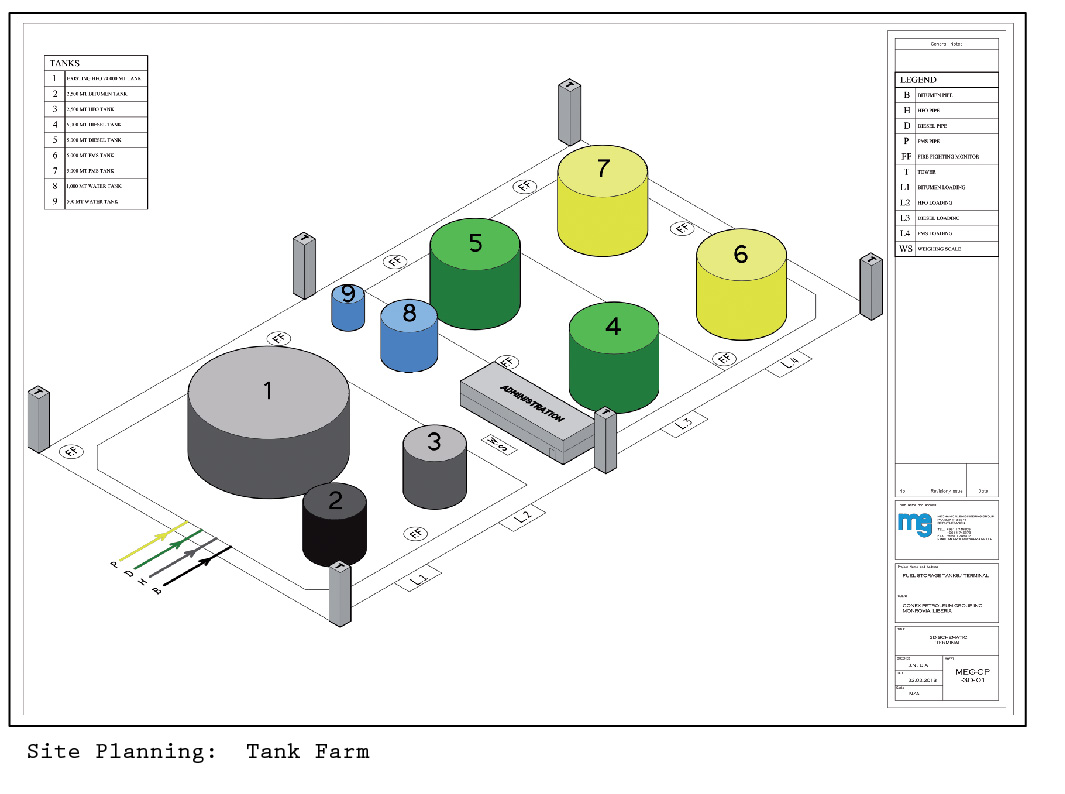

• Bulk Storage Facilities

• Fuel Terminals and Process Piping

• Sea Lines for Tanker Offloading

• Firefighting Installations

• Industrial Pumping Stations

• Industrial Piping

• Pipelines

• Gas Turbine Generators

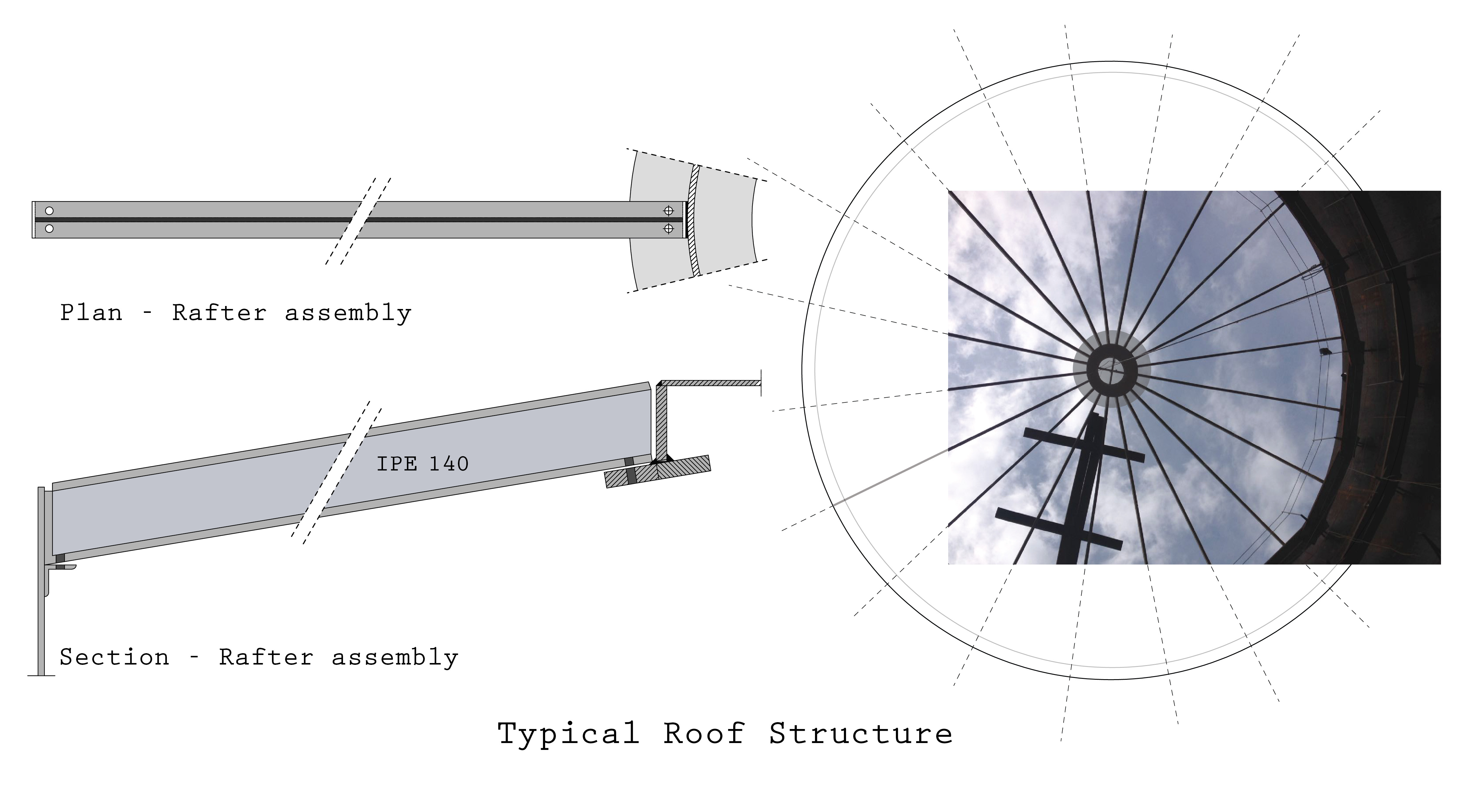

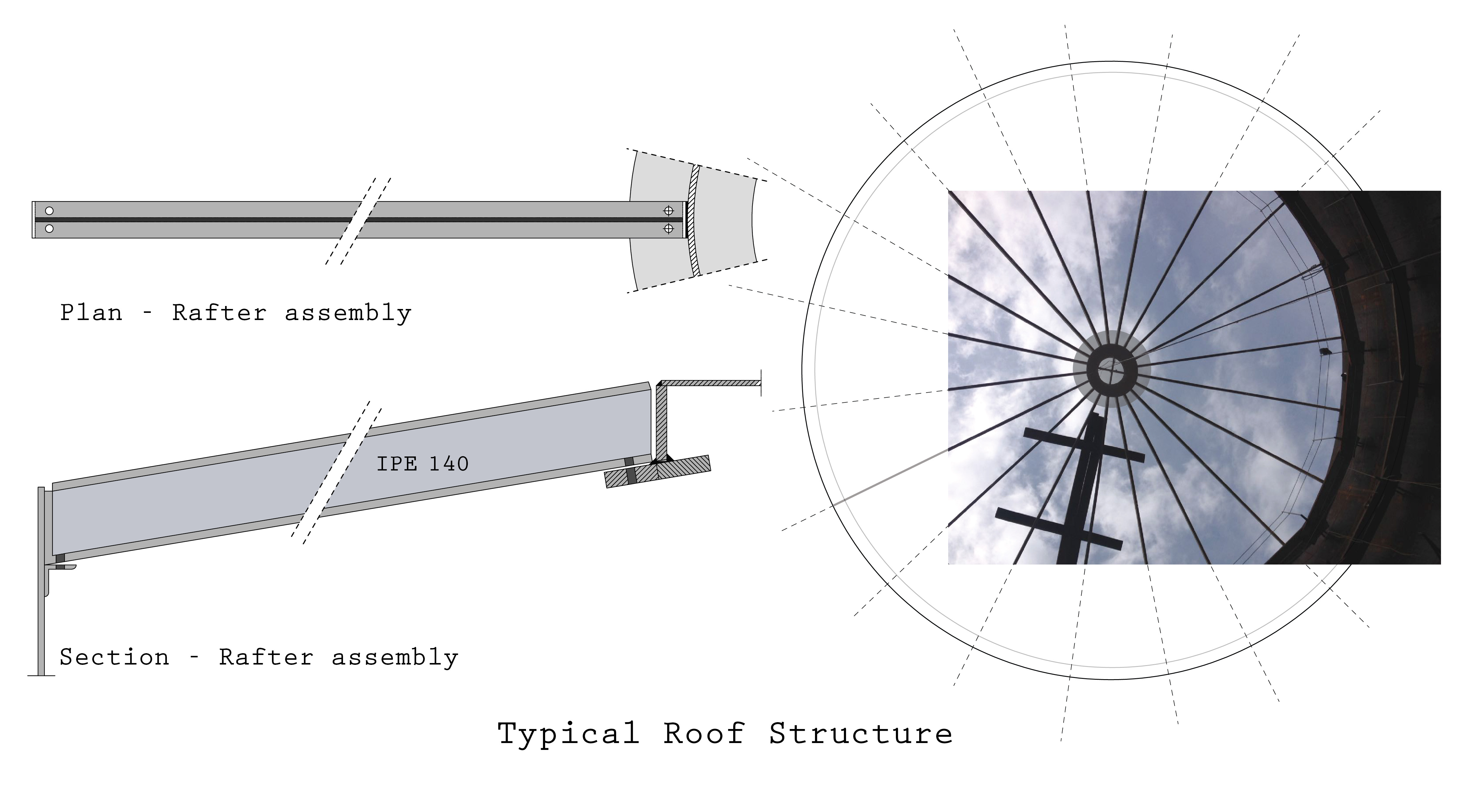

• Steel Structures

• Sheet Metal

• Fabrication / Prefabricationl

• Testing, Adjusting and Balancing

Our objective is to help ensure constructability, maintainability, and sustainability.

MEG is a primary contractor working in various sectors, including public and private; with contracts ranging from fixed-price, cost-plus, design-build-operate, to fast-track construction projects. We perform our work in diverse disciplines. Our construction and installation capabilities include::

• Bulk Storage Facilities

• Fuel Terminals and Process Piping

• Sea Lines for Tanker Offloading

• Firefighting Installations

• Industrial Pumping Stations

• Industrial Piping

• Pipelines

• Gas Turbine Generators

• Steel Structures

• Sheet Metal

• Fabrication / Prefabricationl

• Testing, Adjusting and Balancing

Our objective is to help ensure constructability, maintainability, and sustainability.

COMMISSIONING

Commissioning is not only a validation of systems and equipment operation; it is also a form of quality assurance. Drawing on lessons learned from past projects, MEG commissioning services focus on operability, reliability and long-term profitability of engineered projects, from facility handover through ongoing maintenance.

Our job is to ensure the integrity of all systems, identifying and correcting any design and construction inconsistencies along the way. Our holistic approach starts with a strong understanding of the project requirements and design intent, the systems installed and the desired outcome. We help our clients meet a multitude of challenges that may arise from a project's early stages, such as cost control, schedule adherence, regulatory, safety and environmental compliance, and operational performance.

Further to the completion of Construction services, MEG strives to deliver effective systems completion and handover, assisting with completion checklists and handover documents to the client. Our services include:

• Startup and performance testing

• Development of operations manuals, procedures and checklists

• Technical training for operators and maintenance personnel

• Technical audits of existing facilities for reliability and availability

• Consulting services for operation and maintenance

• Supervision and engineering

• Provision of technicians (field, mechanical, instrumentation, electrical)

• Materials, logistics and coordination

• Certification and handover

Our job is to ensure the integrity of all systems, identifying and correcting any design and construction inconsistencies along the way. Our holistic approach starts with a strong understanding of the project requirements and design intent, the systems installed and the desired outcome. We help our clients meet a multitude of challenges that may arise from a project's early stages, such as cost control, schedule adherence, regulatory, safety and environmental compliance, and operational performance.

Further to the completion of Construction services, MEG strives to deliver effective systems completion and handover, assisting with completion checklists and handover documents to the client. Our services include:

• Startup and performance testing

• Development of operations manuals, procedures and checklists

• Technical training for operators and maintenance personnel

• Technical audits of existing facilities for reliability and availability

• Consulting services for operation and maintenance

• Supervision and engineering

• Provision of technicians (field, mechanical, instrumentation, electrical)

• Materials, logistics and coordination

• Certification and handover

REPAIR AND MAINTENANCE

- Storage Tank Maintenance

With the goal of improving return on capital investments while lowering related annual operation and maintenance costs for our clients, MEG has built on its successes in tank design and construction by also providing the following highly-valued solutions and services for storage tanks and associated facilities, up to a capacity of 35,000 m³:

• Rehabilitation

• Cleaning

• Sandblasting and Coating

• Repair

• Relocation

• Decommissioning

1. Rehabilitation

Whether the result of natural deterioration, accidental damage, or other factors, our team of experts conduct detailed inspections and assessments of existing oil and gas facilities, tank farms, and associating piping networks and equipment to design customized rehabilitation solutions for maximizing the value of your assets and ensuring that any solution will be delivered efficiently and cost-effectively restoring to like-new conditions and. We accomplish this by utilizing proven programs combined with the development of new and innovative products and services, in strict adherence with international standards and regulations, resulting in total solutions for our clients. Our rehabilitation services include:

• Tank inspection programs with detailed reports

• Planning of engineering

• Evaluation for short and long-term management

• Interior cleaning and rehabilitation

• Tank repair

• Ongoing tank management

• Repair work to optimize tank operations

• All future interior and exterior coatings

• Artwork design and application of logos

• Emergency services for immediate on-call responses

• Solutions for structural issues

• Roll and dish plates for roofs, shells and bowls

• Tank accessories

• Roof replacements

2. Cleaning

Common problems with stored products, such as water absorption, phase separation, and microbial growth can lower the quality of your products and hinder the performance of your operation and storage facilities. Therefore, maintaining clean storage tanks and associated piping networks is the most effective approach to ensuring optimal performance of your storage tank facilities and the products that are stored and processed within them. MEG provides professional services to efficiently clean and maintain storage tank facilities for storing various product types including all types of oils, chemicals, asphalt, and other products. Whether it is routine maintenance to remove solids and sludge, decontamination measures, or other purposes, our trained personnel have developed a proven record through years of experience in successfully and effectively completing the most complex of tasks in this regard.

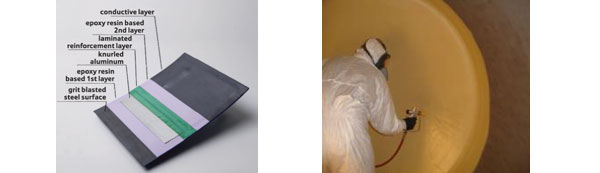

3. Sandblasting and Coating

Surface preparation and protection are critical for the sound operation and durability of storage tanks. Using the correct sandblasting techniques and applying the suitable compliant coating material can ensure that your tanks are well-protected from the interior and exterior for many years against all elements, including climate conditions and aggressive chemicals. MEG has been a regional leader in the abrasive blasting and coating of steel tanks and piping, having successfully completed hundreds of such projects in the MENA area.

Steel surfaces are prepared and blasted according ISO 8501 or SSPC / NACE standards using advanced techniques and equipment. Further to inspection and approval of the blasted surface, the coating process begins whereby the application procedures, coating material specifications, required dry film thickness (DFT) and other aspects are determined in adherence to international standards including but not limited to API RP 652 and ISO 16961.

4. Repair

MEG supports its clients by executing all types of storage tank repairs, regardless of location or severity of damage. All of our repairs meet API 653 tank repair standards and can be as minor as repairing a small leak or valve addition, replacing a sheet in a shell course, installing a new tank floor or as major as providing services to replace a tank. MEG has the experience and the credentialed technicians to deliver exemplary API 653 Tank Repair services.

5. Relocation

MEG has been safely and successfully relocating above-ground storage tanks (AST) throughout its history. With international operations, our engineering procedures have continued to evolve using the latest technology, while focusing on cost and safety concerns. Tank relocation is a valuable tool for tank farm owners and operators, allowing cost-effective and time-saving solutions to make use of unused land or to consolidate assets.

Our relocation services include full design and execution of detailed procedures, in addition to supporting the client in coordinating with the concerned parties to ensure the safe and efficient completion of any relocation task. Prior to relocation, we perform a series of extensive engineering calculations on the related tank(s) or facility, taking into account not only the engineering factors such as stress, but also field conditions such as wind and other natural factors.

6. Decommissioning

MEG recognizes that tank decommissioning can be hazardous and requires intricate planning and coordination to ensure safe and timely execution of such projects. Our field experience and adherence to detailed procedures help minimize the risks involved and have led to the successful completion of tank decommissioning projects in the region, up to a capacity of over 1,000 m3, with zero incidents. In some cases, the material removed within the decommissioning process has been rehabilitated and recycled through advanced treatment procedures, for use in other projects, thus offering our clients significant cost savings while reducing the environmental impact in the process.

Through our dedicated team of professionals, we also provide services to temporarily decommission or permanently abandon storage tanks and associated facilities safely, without the actual removal of the tanks and facilities in question. - Tanker Truck Refurbishment

Timely maintenance of tanker trucks is important for keeping your product in optimum condition during loading/unloading and transportation, while ensuring long term reliability and availability of your truck assets. MEG provides standardized maintenance services for continuous reliable operation of your tanker trucks, in addition to refurbishment services that restore deteriorated tankers to compliant operational condition. Our services are applicable for most products ranging from hydrocarbons such as Jet A-1 to potable water.

Our skilled technicians perform the following refurbishment works in compliance with international standards:

- Restore interior and exterior surfaces using abrasive blasting and treatment techniques, based on the type of steel

- Fabricate, weld and install customized steel parts to replace deteriorated parts

- Apply interior and exterior lining/coating of the tanker frame and shell

- Replace all product lines, piping, hoses, manholes, manifolds, valves, couplings, and others

- Customized artwork design and application of logos

With fast track scheduling, our services ensure that your fleet is always in prime condition for supporting your continuous operation. - Internal Tank Lining

Protecting your above-ground and underground storage tanks against leakage and corrosion is vital for long term operation of your assets and for preserving the value of your investment.

In collaboration with its partner, Wolftank Adisa GmbH (www.wolftank.com), MEG offers innovative tank lining and stratification solutions for above-ground and underground storage tanks using advanced epoxy resins. The application of Wolftank products includes special features such as reduced maintenance time, retention of the original tank volume and continuous monitoring, according to the highest standards of technology and safety. Wolftank products have been successfully used on thousands of storage tanks worldwide, especially underground storage tanks at petrol stations, with substantial cost savings to clients.

MEG tank lining services in partnership with Wolftank offer numerous advantages including:

- Extends assets’ lifecycles, thus avoiding costly and time-consuming tank replacement, particular in underground installations.

- Complete metal corrosion protection

- No future risk of product spillage into the environment

- Makes storage of aggressive chemicals possible, avoiding the use of stainless-steel structures

- Safe manned entry with Wolftank's safety standards and ATEX-rated equipment

- Enables local reparations of particularly affected areas

- Approved for application both on steel construction for corrosion and on concrete structures against degradation

- Short operation and down time since no construction work is required

- Systems have been tested and approved by the German TÜV and comply with European and international regulations

Please visit www.wolftank.com for additional information on Wolftank products.

PROJECT MANAGEMENT

As a primary mechanical engineering, procurement and construction (EPC) contractor, MEG has successfully executed a portfolio of highly complex projects in some of the most demanding locations in the region. With a reputation of delivering cost-effective projects on schedule, we offer clients a complete solution to project management that helps assure a project is delivered on-time and within budget.

Our integrated team approach delivers innovative, time and cost-effective management services regardless of the size and scope of the project. Applying our proven experience within our business domains, knowledge base, and extensive library of best practices and lessons learned, MEG offers a range of project management tools for every phase of the project, integrating the activities of all parties for timely completion and delivery of projects within the established client objectives of time, quality, cost, safety and environment.

MEG’s Project Management services include:

• Manage the site(s) for all contractors

• Supply common services to contractors

• Handle all contractor inquiries and claim analysis

• Provide interface management and services

• Monitor and report on progress of work and budgets

Our integrated team approach delivers innovative, time and cost-effective management services regardless of the size and scope of the project. Applying our proven experience within our business domains, knowledge base, and extensive library of best practices and lessons learned, MEG offers a range of project management tools for every phase of the project, integrating the activities of all parties for timely completion and delivery of projects within the established client objectives of time, quality, cost, safety and environment.

MEG’s Project Management services include:

• Manage the site(s) for all contractors

• Supply common services to contractors

• Handle all contractor inquiries and claim analysis

• Provide interface management and services

• Monitor and report on progress of work and budgets